Two versions have been made, namely, an integrated fully mechanized, 3 tons/day plant; and a semi-manual 250kg/day plant. There are PRODA made machines for each involved operation previously done manually: Peeling Dewatering; Depulping; Frying; Sieving/Grading; and Bagging, Chipping/Shredding, single Hopper, High output, Double barrel Hopper, Manual Cassava Tuber Harvester.

NEW IMPROVED VERSION OF CASSAVA PEELING MACHINE (Patented)

PRODA DOUBLE BARREL GRATER Capacity 1 ton/hr.

PRODA SELF-ACTION GRATER (single) Capacity 300kg/hr.

PRODA HYDRAULIC JACK PRESS.

PRODA VIBRATING SIEVE.

GARRI ROTARY SIEVE.

COMMUNAL GARRI FRYER.

This equipment is built to handle tubers of all shapes and sizes. Chipping is accomplished as cassava (dropped tail-first into one or many of the holes provided) fall across the path by of horizontal knives oscillated about a pivot, by a quick –return mechanism.

PRODA CASSAVA CHIPPING MACHINE

PRODA KERO-HEATED OVEN/DRYER (LARGE SIZE)

PRODA INDUSTRIAL ELECTRIC DRYER (FOR CASSAVA CHIPS AND OTHER GRAINS)

PRODA MICRONISER WITH CYCLONE BAGGING HOPPER (FOR COLLECTION OF CASSAVA FLOUR)

This, (1000 litres of palm oil/day), plant consists of complementary units namely; Palm Fruit Stripper, Palm Fruit Boiler; Palm Fruit Digester; Palm Oil Press; Palm Kernel nut fibre separator, Palm Kernel Cracker; Palm Kernel Shell Separator; Palm Kernel Oil Extractor; Integrated cracker/Shell Separator, Horizontal Shaft Palm Fruit Digester.

PRODA INTEGRATED PALM KERNEL CRACKER /SEPARATOR (Patented) Capacity 1 ton/hr

PRODA PALM KERNEL CRACKER. Capacity 1ton/hr

PRODA Palm Fruit Digester.

PRODA Palm Fruit Boiler

PALM KERNEL OIL (PKO) EXPELLER Capacity 480kg/hr

PRODA Palm Fruit Debuncher

Palm Oil Press.

Three versions of fish meal Pelleting machine, (small manual, medium motorized, and heavy duty motorized), have been made by PRODA, and are in service in over 5 locations nation-wide. A cassava Pelleting machine was also made for the National Root Crops Research Institute, Umudike; for production of Cattle and other animal feeds. This equipment integrates other PRODA machineries, eg. Hammer Mill; Dry and Wet Mixer, Dryers etc., to compose viable low-cost animal feed packaging Industries

The Maize sheller removes the maize grains from the cob in a very faster manner. The machine is designed to remove and separated the cob, the grain and the chaft. All these components are collected at different points on the machine. The machine has a capacity of about 400kg per hour and a separation efficiency of up to 87%. Minimal losses of grains are observed.

Other Machine Specifications

Innovation

This is value addition to Soya Bean through mechanized process technology, in addition to providing a rich protein source for adults, infants, pregnant and lactating women, invalids, and malnourished children. The components of the plant are: Toaster, Dehusker, separator, micro-mill, cyclone I and cyclone II

PRODA SOYA BEAN TOASTER

PRODA SOYA BEAN DE-HULLER/SEPARATOR, FRONT VIEW

PRODA SOYA BEAN MICRO MILL FRONT VIEW

PRODA MICRONISER CYCLONE

PRODA SOYA BEANS CYCLONES 1 & 2

The electric dryer dries both the maize and the corn together. About 250kg of maize are arranged in cabinet and heat is supplied to the dryer via electric elements and blower. Drying is very effective with efficiency up to 89%. The machine is designed to handle up to 250kg per batch of 1 hr.

Other Machine Specifications

Innovation

This equipment is designed for drying agricultural produce. The temperature can be regulated to suit different drying operations. Applications: Used in baking of bread, cakes, etc and drying of fish and agricultural produce to different moisture contents. It can also dry fish. Principle of Operation: Like any other baking oven, it has baking/drying trays and the heat is indirectly transferred to the trays. A temperature gauge indicates the operating temperature.

Technical Data

This machine is designed to reduce particle sizes of grain, bones and other hard dry substance to micron and sub micron sizes. Application: This machine can be used by Food processing industry, pharmaceutical, feed mill industry, paint industry and ceramic industry. Principle of Operation: The use of heavy duty Inertia Roller is applied to bring about the size reduction to micron and sub micron size.

Technical Data

The pencil project has witnessed tremendous achievements since its inception. The pencil factory under installation is billed to produce a minimum of 15 million pencils (HB and 2B) per annum using local raw materials such as graphite, clay and wood. That is to say, the project is aimed at 100% local content. The Institute has carried out feasibility report on the project and established links with some companies in China for technical know-how, machinery, production accessories and training/man development in the area of pencil making.

Immediately it was conceived and approval given, design of pencil factory buildings, housing Graphite Beneficiation, pencil lead production, and pencil making commenced. In addition, arrangements were made for procurement of pencil making machinery from China and commencement of installation. About 21 pencil making machines performing specific functions were installed and awaiting test production.

PRODA SLURY/PAINT MIXERS

PRODA FUFU POUNDER

PRODA CONFECTIONARY MIXER

PRODA RIBBON MIXER

PRODA CONFECTIONARY KNEADER MACHINE

PRODA CRUSHING MILL

The Multiple Purpose Roasting Machine roasts items ranging from meat, fish, Grains, cocoa nut etc. The machine is designed to handle large quantity of material up to 50kg per batch. The machine operates on a very low speed and uses thermostatically controlled heating elements to generate the heat required for the roasting. The machine is built purely on stainless steel which makes the roasted items very neat for human consumption

Specifications:

Innovations:

This machine is designed to extract juice from edible fruits e.g. Orange, Pineapple, Cashew, Guava, etc. This equipment is completely built with stainless steel materials in compliance with standards of the food industry.

Specifications

PRODA INDUSTRIAL POULTRY WASTE DRYER: This project is a case of conversion of waste to wealth. The machine is designed for drying wet poultry droppings for better storage and packaging. The dried product can last for about one year and can be used as equivalent to fertilizer. It can compete favourably with synthetic fertilizer when properly preserved. Drying and storage of this manure helps in eliminating waste. The product is environmentally friendly and sustainable.

Specifications

This equipment is a closed heating or cooking apparatus, viz; fire- grate, a Kiln or Oven for various manufacturing operations. There are various types of Stoves namely; Kitchen Stove, Wood burning Stove, Electric Stove, Pressure cooker, Coal Stoves, Gas Stoves, Biomass Stoves, etc.

They have Multi-solid fuel utilization capability:

Usable fuels for the appliances include:

PRODA SOLID BIOMASS/COAL FUEL COOKING STOVE

PRODA SAW DUST/RICE HUSK FUEL COOKING STOVE

PRODA MULTI-PURPOSE COAL/BIOMASS FUEL COOKING STOVE (MANY)

PRODA MULTI-PURPOSE COAL/BIOMASS FUEL COOKING STOVE (SINGLE)

A gas-heated industrial Steam Cooker has been developed by PRODA for Institutions and fast foods industries. This equipment was put to use at the Nigeria Airways, UACN (Foods) Ltd., Nigeria prisons etc The technology preserves the flavour, nutritional value colour of the food, and immensely reduces the cooking time.

The virtual dependence of the country on petroleum and petroleum related products has relegated the use of coal to the back ground. The main product of coal carbonization (smokeless solid fuel) which is also an alternative to firewood is intended to solve the twin problems of soil erosion in the south and desert encroachment in the northern parts of Nigeria.

CARBONIZED COAL

PRODA STEAM COOKER COAL FIRED

PRODA COAL BRIQUETTES

A coal –fired Furnace for cottage foundries, and oil –fired Tilting Crucible Furnace have been developed in PRODA. These accommodate pots upto 300kg holding capacity, and have been successfully tested in producing several castings, e.g. brake drums, gears, pulleys, flywheels etc. A vertical spin casting machine of 10kg holding capacity, has also been developed by PRODA to facilitate production of stable thin-wall section castings such needed in air cooled engine crankcase, electric motor casings etc. This equipment is now undergoing tests. PRODA has developed a method of processing local graphite to over 90% purity for producing crucible pots, pencils; auto parts etc.

CRUCIBLE POT

MULTI-PURPOSE GRINDER WITH MECHANICAL PARTS AND MOULD

WOODEN MOULD

MOULDS FOR CASTINGS

PRODA has produced a 5hp centrifugal water pump for domestic, trade and agricultural use. The pump, according to choice may be powered by either an electric motor or an engine. Since FEAP who had committed itself to the commercialization of the pump is now defunct other investors from the OPS are encouraged to embrace the product. In the meantime, quality improvements continue to be made on the pump.

PRODA has developed and produced an electric welding machine. This machine is suitable for joining metals and performs very well. Electric welding machines are used in thousands all over the country both for domestic and industrial structures. Therefore local industries could be developed at all nook and crunies of the country in order to service this domestic and industrial need. This could then create job opportunities for the unemployed.

| Machine Description | Quantity |

|---|---|

| Input voltage | 220v a/c single phase |

| Frequency | 50Hz |

| Coolant | Transformer oil |

| Electrode gauges | 12 – 8 |

| Length | 46.5 cm |

| Width | 41 cm |

| Height | 41 cm |

| Volume | 78.2 litres |

Used by SME's for metal fabrications. Can engage metal of up to 3mm thickness

| Machine Description | Quantity |

|---|---|

| Input voltage | 220v a/c single phase |

| Frequency | 50Hz |

| Coolant | Air at NTP |

| Electrode gauges | 12 – 10 |

| Length | 46 cm |

| Width | 31 cm |

| Height | 30.5 cm |

| Volume | 43.5 litres |

Used by SME's for metal fabrication. Engage metals of up to 1mm thickness

PRODA evolved a number of traffic control system (The plain automatic traffic controller, universal controller and sensitive traffic controller). The latest model (The sensitive traffic controller) has been publicly demonstrated as the most suitable for controlling traffic at busy junction in Nigerian cities. The main feature of this system is that it directs traffic like a traffic policeman. It does not operate on fixed time basis. If there is no traffic on any lane, it will by-pass them and switch immediately on the next lane. It's successfully controlled traffic at the Enugu/Abakaliki road, Abakpa junction then and at a heavy junction at Ikom. This unit has been developed up to the level that it can now go into production.

| Machine Description | Quantity |

|---|---|

| Input voltage | 220v a/c single phase |

| Frequency | 50Hz |

| Timing | Adjustable according to vehicle traffic |

| Power max. | 1.9kw Av. – 1.0kw |

Used to control vehicle traffic in a 4-way junction. This equipment is designed for busy junctions of all Nigerian cities. It has been hailed by the Traffic Policemen as being better than what they have been used to, including imported models.

This is a system that uses sun light collected during day time to provide quality light at night in the environment where the system is installed. It functions automatically and needs no attendance. It is best suited in providing night light along high ways, streets, compounds, gardens, etc. The light from the system is useful in deterring criminals that use darkness to hide and in extending the socio-economic life of communities where they are installed.

| Machine Description | Quantity |

|---|---|

| Battery | 12V |

| Amperage | 100AH |

| Light | 35W LED's |

| Module size | 150w |

| Duration | Dusk to dawn. |

Illumination of Highways and premises; domestic, industrial and institutions.

This is a system that uses sun light as fuel to generate usable electricity. The electricity so generated can be used in homes, offices and factories to electrically power equipments. It is the easiest means of achieving electricity generation in areas where public utility power is difficult to install. It does not involve the erection of poles, transformers, long distance cabling. The system can be designed and installed in various capacities(1kv, 3kv, 5kv etc). The system is composed of modules (solar panels) and other balance of systems components such as inverters, charge controllers, wires, switches, etc.

As specified by the client

Used to control vehicle traffic in a 4-way junction. This equipment is designed for busy junctions of all Nigerian cities. It has been hailed by the Traffic Policemen as being better than what they have been used to, including imported models.

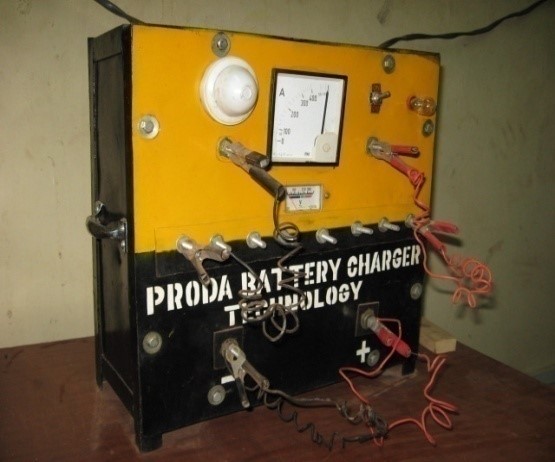

Industrial Battery Charger: Battery chargers are useful and relevant. They are easy to produce because the required components are readily available. PRODA has successfully produced an industrial battery charger capable of charging up to three lead acid batteries at a time.

| Machine Description | Quantity |

|---|---|

| Input voltage | 220v |

| Frequency | 50Hz |

For charging up to 3 lead acid batteries at a time.

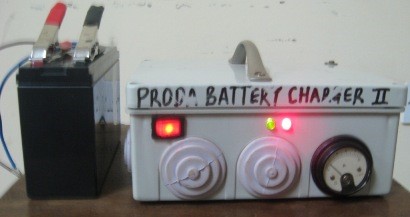

| Machine Description | Quantity |

|---|---|

| Input voltage | 220v |

| Output voltage | 12v dc |

| Frequency | 50Hz |

For charging of car batteries.

The Electric Vehicle conversion done in PRODA used a small Toyota Starlet car. The converted vehicle can carry the full passenger load of four persons and cover up to (80) kilometers per hour. It has a range of about one hundred (100) kilometers for battery recharge. It is powered by a seventy-two (72) volts d.c. battery (6 nos, 12 volts batteries) capable of five thousand (5,000) revolution per minute. This is the first attempt in the Institute in converting petrol fired engines to Electrical power driven. It is hoped that further R & D will result to more efficient and economic version of the Electric Car.

Cottage Pottery plants for entrepreneurs can be packaged from PRODA made equipment, such as Blungers, Filter Press, Moulds, Jigger-Jolley Machine, Porter's Wheel, Drying Booth, Spray/Painting Booth, Glazing Bath, and Firing Kiln (gas or electric). The plant produces table and decorative wares which are well received by consumers.

PRODA brick moulding machine

Potters wheel (jigger) jolly

PRODA now possesses considerable proficiency in pottery production technology. Since 1972, the Institute has operated a self-contained limited production outfit for commercial manufacturing of ceramic table and decorative wares, building bricks and blocks, industrial refractory bricks etc. These have been in great demand and sold nationwide. A number of housing estates in Enugu/Anambra States and PRODA itself were built with PRODA Bricks/blocks.

Through this experience, PRODA has innovated on a number of related production equipment such that the Institute can now package cottage pottery plants for entrepreneurs.

PRODA Building Bricks

PRODA Newly Produced Assorted Decorative Ceramics Wares

PRODA has developed body and glaze formulations for porcelain electrical insulators suitable for high and low tension applications on overhead electric power lines. The products were tested at the University of Lagos in 1988-89, and surpassed BS 137 – 1970 conditions. The product won the National Science prize (1991) and the Nigerian Academy of Sciences/MAN Award (1990).

Low Voltage Insulator (240-415 Volts)

High Voltage (3.3-11KV)